Discover the Benefits of High Precision Granite for Your Industry

By:Admin

Founded in 1995, High Precision Granite Company has built a solid foundation in the local market, developing a strong customer base and a reputation for excellence. The company has distinguished itself with its commitment to quality and precision, offering a range of granite products that meet the highest industry standards.

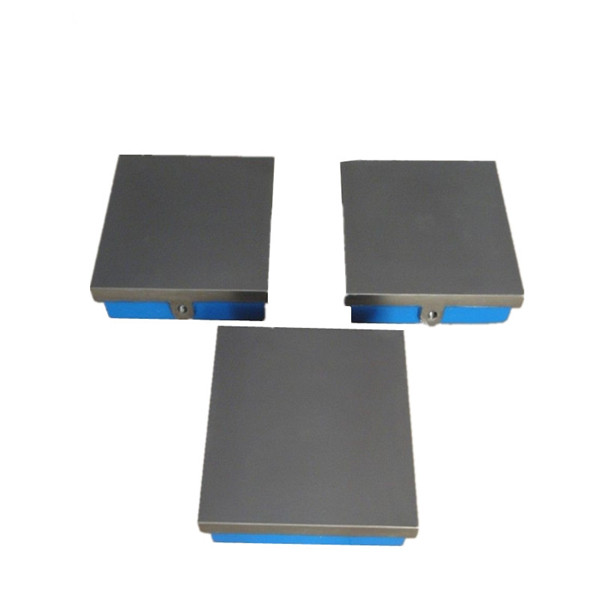

The company's range of products includes precision granite surface plates, granite squares, and granite parallels, all of which are manufactured to exacting standards. These products are widely used in industries such as aerospace, automotive, and manufacturing, where precision and accuracy are critical.

"We are proud to announce our expansion into the global market," said the company's CEO. "We have spent years building our reputation for quality and precision, and we are excited to bring our products to customers around the world."

High Precision Granite Company's expansion comes at a time when the demand for high-quality granite products is on the rise. As industries continue to prioritize precision and accuracy, the need for reliable granite products has never been greater.

The company's products are known for their exceptional flatness, surface finish, and overall durability, making them ideal for a wide range of applications. With a commitment to continuous improvement and innovation, High Precision Granite Company is well positioned to meet the evolving needs of its customers.

In addition to its product offerings, the company also provides custom machining services to meet the unique requirements of its customers. With a team of skilled technicians and state-of-the-art equipment, High Precision Granite Company can create custom solutions for customers with specific needs.

"We understand that every customer has unique requirements, and we are dedicated to providing customized solutions that meet their exact specifications," said the company's CEO. "Our team is highly skilled and experienced, and we have the capabilities to tackle even the most challenging projects."

As part of its global expansion, High Precision Granite Company has also invested in enhancing its supply chain and distribution network. By strategically partnering with distributors and agents in key international markets, the company aims to make its products more accessible to customers worldwide.

The company's commitment to quality, precision, and customer satisfaction has earned it a strong reputation in the industry. With its expansion into the global market, High Precision Granite Company is poised to further solidify its position as a leading provider of high-quality granite products.

"We are excited about the opportunities that lie ahead as we expand into the global market," said the company's CEO. "Our focus remains on delivering exceptional products and services to our customers, and we are confident that our expansion will enable us to serve even more customers around the world."

As High Precision Granite Company continues to make strides in the industry, its dedication to quality and precision remains unwavering. With its expanded global presence, the company is well positioned to meet the growing demand for reliable granite products and uphold its reputation as a trusted industry leader.

Company News & Blog

Discover the Advantages of a Cutting-Edge 3D Welding Fixture System

XYZ Company Unveils Revolutionary 3D Welding Fixture System[City, Date] - XYZ Company, a leader in manufacturing and engineering solutions, has recently introduced its groundbreaking 3D Welding Fixture System. This innovative technology is set to revolutionize the welding industry by streamlining processes and improving efficiency.The new 3D Welding Fixture System developed by XYZ Company is a result of years of intensive research and development. It offers a comprehensive solution to the challenges faced by traditional welding fixture systems, making it a game-changer for businesses in the welding industry.Traditional welding fixtures are often time-consuming and require extensive manual adjustments, resulting in a significant loss of productivity. However, XYZ Company's new 3D Welding Fixture System eliminates these drawbacks by utilizing state-of-the-art 3D scanning and modeling technology.The key advantage of XYZ Company's 3D Welding Fixture System is its ability to create precise and accurate fixtures quickly. The system utilizes advanced scanning technology to capture the precise dimensions and contours of the workpiece. This information is then used to generate a virtual 3D model of the fixture, allowing for precise configuration and adjustment without the need for lengthy manual measurements.Furthermore, the fixture can be easily adjusted and modified using the 3D model, reducing the time and effort required for physical adjustments. This feature significantly improves efficiency and reduces downtime, enabling businesses to meet tight deadlines and increase overall productivity.Another notable feature of XYZ Company's 3D Welding Fixture System is its versatility. The system can be used for a wide range of welding applications, including complex and intricate designs. Its adaptive capabilities allow for easy and precise adjustments to accommodate various workpieces, resulting in a flexible solution for diverse welding requirements.The incorporation of advanced automation technology within the 3D Welding Fixture System further enhances its efficiency. The system integrates seamlessly with robotic welding systems, enabling precise alignment and synchronization between the fixture and welding robot. This automation minimizes human errors and optimizes the welding process, ensuring consistent and high-quality welds.The introduction of this innovative 3D Welding Fixture System by XYZ Company marks a significant advancement in welding technology. With its ability to streamline processes, increase productivity, and enhance precision, this system is set to become the new industry standard for welding fixtures.XYZ Company has a long-standing reputation for delivering cutting-edge manufacturing and engineering solutions. With a focus on research and development, the company is committed to pushing boundaries and bringing revolutionary technologies to the marketplace. The introduction of the 3D Welding Fixture System is a testament to XYZ Company's dedication to innovation and its commitment to empowering businesses with advanced tools.As the welding industry continues to evolve, XYZ Company's 3D Welding Fixture System is expected to have a profound impact. Companies in various sectors, including automotive, aerospace, and construction, will undoubtedly benefit from this groundbreaking technology. By improving efficiency, reducing downtime, and enhancing precision, XYZ Company's 3D Welding Fixture System will enable businesses to meet growing demands and stay ahead of the competition.About XYZ Company: XYZ Company is a leading provider of manufacturing and engineering solutions, specializing in delivering cutting-edge technologies to industries worldwide. With a focus on innovation and continuous improvement, XYZ Company has built a reputation for excellence and reliability. By leveraging state-of-the-art technologies, the company aims to empower businesses with advanced tools and solutions to drive success in a rapidly changing market.

Top Supplier of High-Quality Granite Machine Spare Parts Offers Unbeatable Value

Title: Leading Manufacturer of Granite Machine Spare Parts Expands Product Line to Meet Industry DemandIntroduction:In today's rapidly evolving industrial landscape, the need for high-quality spare parts and components is paramount. Recognizing this demand, Manufacturer of Granite Machine Spare Parts (MGMSP), a renowned industry player, has been continually expanding its product line to cater to the increasing needs of the granite machine sector. With a strong commitment to innovation and customer satisfaction, MGMSP has established itself as a reliable manufacturer and supplier of precision-engineered spare parts for granite machines. In this news article, we will delve into the company's journey, latest product offerings, and their impact on the industry.Company Overview:Established in [Year], MGMSP has rapidly established a reputation for delivering exceptional quality spare parts, consistently exceeding customer expectations. The company's state-of-the-art manufacturing facility, coupled with a team of highly skilled engineers and technicians, enables MGMSP to develop and produce a diverse range of spare parts that meet strict industry standards.Having recognized the importance of employing cutting-edge technology, MGMSP has invested significantly in its research and development capabilities, allowing the company to stay ahead of the competition. MGMSP's commitment to quality and continuous improvement has earned them a loyal customer base in the granite machine industry.Expansion of Product Line:Responding to the evolving demands of its customers, MGMSP has expanded its product line, offering an extensive range of granite machine spare parts. The company's new offerings include advanced components such as cutting tools, saw blades, bearings, shafts, motors, control systems, and electrical parts, among others. By broadening their product line, MGMSP aims to provide comprehensive solutions to its customers' growing needs, streamlining the maintenance and repair process for granite machines.These new additions to the product line have been developed through extensive research and collaboration with prominent industry experts. MGMSP's highly skilled team works in close association with its customers, ensuring precise customization of spare parts to suit their specific requirements. The company's adherence to quality benchmarks ensures that their spare parts not only enhance the efficiency and longevity of granite machines but also minimize downtime, resulting in increased productivity for their customers.Industry Impact:MGMSP's expanded product line of granite machine spare parts has already made a significant impact on the industry. By addressing the scarcity of high-quality spare parts in the market, MGMSP has become a preferred partner for numerous businesses operating in the granite machine sector.The availability of a comprehensive range of spare parts under one roof has simplified the procurement process for industry professionals, reducing lead times and ensuring uninterrupted operations. MGMSP's commitment to quick and efficient delivery, combined with their competitive pricing, has further strengthened their position as a reputable and reliable spare parts supplier.Furthermore, MGMSP has established a strong global presence by exporting its spare parts to various countries across the globe. Their products have been well received by international clients, underscoring the company's commitment to providing high-quality spare parts to meet the diverse needs of the global granite machine industry.Conclusion:Manufacturer of Granite Machine Spare Parts (MGMSP) has successfully positioned itself as a leading provider of precision-engineered spare parts for the granite machine industry. Through continuous innovation and expansion of their product line, MGMSP has consistently met the ever-growing demands of their customers. By offering a comprehensive range of high-quality spare parts, the company has significantly contributed to streamlining the operational efficiency of businesses and strengthening the granite machine sector as a whole. MGMSP's dedication to quality, customer satisfaction, and technological advancement ensures an even brighter future for the company and the industry it serves.

Benefits of Spheroidal Cast Iron and Its Applications

Spheroidal Cast Iron – An Essential Material for Industrial ManufacturingSpheroidal cast iron, also known as ductile iron, is a type of cast iron that has been treated with magnesium to change the graphite structure from flakes to nodules. This process significantly improves the strength and ductility of the iron, making it an essential material for various industrial applications. The unique properties of spheroidal cast iron make it a preferred choice for manufacturing components that require high strength, toughness, and wear resistance.One of the leading producers of spheroidal cast iron is {} (the Company). With decades of experience in the foundry industry, the Company has established itself as a trusted supplier of high-quality spheroidal cast iron products to customers worldwide. The Company's state-of-the-art manufacturing facilities and stringent quality control processes ensure that their products meet the highest industry standards.The Company offers a wide range of spheroidal cast iron products, including but not limited to, nodular cast iron pipes, fittings, valves, and other industrial components. These products are widely used in various sectors such as water and wastewater management, oil and gas, automotive, construction, and general engineering.One of the key advantages of spheroidal cast iron is its exceptional mechanical properties. The nodular graphite structure in the material improves its tensile strength, yield strength, and impact resistance, making it suitable for applications that require high mechanical performance. Additionally, spheroidal cast iron exhibits good machinability, allowing for easy fabrication of complex components with tight tolerances.Furthermore, spheroidal cast iron has excellent corrosion resistance, making it a preferred material for applications where exposure to harsh environments is a concern. The Company's spheroidal cast iron products undergo rigorous testing to ensure they can withstand corrosive substances, high pressures, and extreme temperatures, making them ideal for use in demanding industrial settings.In addition to its mechanical and corrosion-resistant properties, spheroidal cast iron also offers good thermal conductivity and damping capacity. These characteristics make it suitable for applications that involve heat transfer and vibration damping, such as in the manufacturing of machinery and equipment.The Company's commitment to continuous improvement and innovation has led to the development of advanced spheroidal cast iron grades that meet the evolving requirements of modern industrial manufacturing. By leveraging the latest technologies and metallurgical expertise, the Company is able to offer tailored solutions to meet specific customer needs, ensuring the highest level of performance and reliability.With a strong focus on sustainability and environmental responsibility, the Company utilizes eco-friendly production processes and materials in the manufacturing of spheroidal cast iron. By minimizing waste and energy consumption, the Company aims to reduce its environmental footprint while delivering high-quality products to its customers.As a global leader in the production of spheroidal cast iron, the Company is dedicated to providing exceptional customer service and technical support. Their team of experienced engineers and metallurgists work closely with customers to understand their unique requirements and provide expert guidance on material selection, design optimization, and product performance.In conclusion, spheroidal cast iron plays a crucial role in the industrial manufacturing sector, offering a unique combination of mechanical strength, corrosion resistance, and thermal properties. As a pioneering producer of spheroidal cast iron, the Company continues to drive innovation and set new standards for quality and performance in the industry. With a strong commitment to excellence and sustainability, the Company remains at the forefront of delivering advanced spheroidal cast iron solutions to meet the demands of today's most challenging applications.

Revolutionizing Welding: The Latest Innovations in 3D Welding Tables

Title: Leading Welding Table Manufacturer Revolutionizes the Industry with 3D TechnologyIntroduction:Innovation in the welding industry has taken a significant leap forward as a renowned welding table manufacturer introduces cutting-edge 3D technology to their production process. This groundbreaking development ensures improved efficiency, accuracy, and convenience for welders worldwide.With their commitment to continuous improvement and groundbreaking solutions, the company aims to transform the welding experience and set a new standard in the industry. By leveraging 3D technology, they have revolutionized the manufacturing process, enhancing welding tables' quality while reducing production time and costs.3D Welding Table Manufacturer Redefines Quality and Precision:The integration of 3D technology into the manufacturing process allows the company to create welding tables with unparalleled precision and quality. Through the use of computer-aided design (CAD) software and advanced additive manufacturing techniques, they can develop intricate weld fixtures and complex geometries that were previously challenging to achieve.This newfound precision enables welders to improve their workmanship by providing optimal support and stability during the welding process. The 3D tables' superior flatness guarantees quality welds, as the surface ensures the components being worked on remain securely in position, minimizing distortion.Streamlining Work Processes:Not only does the incorporation of 3D technology enable the creation of high-quality welding tables, but it also streamlines work processes for welders. By implementing automated manufacturing processes, the company significantly reduces the time required to produce welding tables while increasing their production capacity.Moreover, the ability to customize welding tables based on welders' specific requirements adds a new level of versatility. Welders can now request tables with unique dimensions, fixture placement, or even integrated clamping systems, ensuring that their equipment perfectly suits their welding needs. This customization not only enhances the welding experience but also boosts overall productivity.Sustainable and Environmentally Friendly Initiatives:In addition to enhancing welders' efficiency and productivity, the 3D welding table manufacturer is also committed to sustainable and environmentally friendly initiatives. By adopting 3D printing technology, they reduce material waste during production considerably. This eco-conscious approach aligns with their vision of minimizing their carbon footprint and contributing positively to the environment.Furthermore, the company utilizes durable, high-quality materials in the production of their welding tables, ensuring longevity and reducing the need for frequent replacements. This sustainable manufacturing approach not only benefits the environment but also enhances welders' operational efficiency by providing robust and long-lasting equipment.Customer-Centric Approach:The company's commitment to customer satisfaction is reflected in their customer-centric approach. They understand that every welder has unique requirements and aims to provide individualized solutions, exceeding customer expectations.Through tailored customer support and after-sales services, they ensure that welders have access to continuous assistance throughout their welding journey. This aspect of their business sets them apart from competitors, as they prioritize creating lasting relationships with their customers.Future Prospects and Expansion:With the successful integration of 3D technology into their welding table manufacturing process, the company is poised for growth and expansion. Beyond gaining recognition within the welding industry, they foresee potential collaborations with other industry players interested in adopting their groundbreaking technology.Additionally, they plan to further enhance their product range by exploring advanced technologies such as artificial intelligence (AI) and Internet of Things (IoT) applications. These advancements will undoubtedly contribute to empowering welders and further improving their overall welding experience.Conclusion:As the welding industry continues to progress, the incorporation of 3D technology in the manufacturing process significantly impacts its future. This innovative welding table manufacturer has taken a bold step forward in revolutionizing the industry, transforming the way welders work. With their commitment to quality, precision, and sustainability, they have set a new standard for the industry, providing welders worldwide with efficient, reliable, and customized solutions.

Durable Cast Iron Machine Bed for Reliable Performance

Cast Iron Machine Bed: The Foundation for Precision EngineeringIn the world of precision engineering, having a strong and reliable foundation is essential for delivering high-quality and accurate products. This foundation often comes in the form of a cast iron machine bed, a crucial component in all types of machining centers and metalworking equipment. The cast iron machine bed serves as the base for the entire machine, providing stability, vibration damping, and support for the moving components. At the heart of every cast iron machine bed is the company, a leading manufacturer of precision machine tools and metalworking equipment. With a rich history spanning over several decades, the company has established itself as a trusted name in the industry, known for producing innovative and reliable products. The company's commitment to quality and precision engineering is evident in the design and manufacturing of their cast iron machine beds, which are widely regarded as some of the best in the industry.The cast iron machine beds produced by the company are made from high-quality cast iron, known for its exceptional strength, stability, and vibration damping properties. The company utilizes advanced casting techniques and machining processes to ensure that each machine bed meets the highest standards of precision and accuracy. In addition, the company's team of experienced engineers and technicians works tirelessly to optimize the design and performance of the machine beds, taking into account factors such as thermal stability, rigidity, and damping characteristics.One of the key advantages of the company's cast iron machine beds is their excellent damping properties, which help to minimize vibrations and ensure smooth and precise machining operations. This is particularly important in high-speed machining applications, where even the slightest vibration can lead to reduced product quality and decreased tool life. The company's machine beds are designed to effectively dampen vibrations and maintain stability, resulting in superior surface finishes and tight tolerances on machined parts.Furthermore, the thermal stability of the company's cast iron machine beds is another critical factor that sets them apart from the competition. As machines run at high speeds and generate significant amounts of heat, it is essential for the machine bed to maintain its dimensional stability and prevent thermal distortion. The company's machine beds are engineered to have minimal thermal expansion and excellent heat dissipation properties, ensuring consistent and accurate machining performance even under the most demanding conditions.The company's dedication to continuous improvement and innovation is reflected in their ongoing research and development efforts for cast iron machine beds. By leveraging the latest technologies and materials, the company aims to further enhance the performance and capabilities of their machine beds, meeting the evolving needs of the industry. Additionally, the company places a strong emphasis on customer feedback and collaboration, working closely with their clients to tailor solutions that address specific machining challenges and requirements.As the manufacturing industry continues to demand higher levels of precision and productivity, the importance of a reliable and high-quality cast iron machine bed cannot be overstated. With the support of the company's expertise and commitment to excellence, customers can be confident in the performance and reliability of their machine beds, knowing that they serve as the foundation for precision engineering.In conclusion, the cast iron machine beds produced by the company are a testament to their unwavering dedication to quality, precision, and innovation. With their exceptional damping properties, thermal stability, and continuous improvement efforts, the company's machine beds set the standard for excellence in the industry, providing the foundation for precision engineering that customers can rely on.

High-Quality Cast Iron Measuring Tools for Manufacturing

is a leading manufacturer of cast iron measuring tools which are widely used in various industries such as construction, engineering, and manufacturing. With a strong focus on innovation and quality, has established itself as a trusted name in the industry.The company offers a wide range of cast iron measuring tools including squares, levels, straight edges, and protractors. These tools are designed to provide accurate and reliable measurements, making them essential for any professional or DIY enthusiast. takes pride in its state-of-the-art manufacturing facilities which are equipped with advanced technology and a team of skilled professionals. The company's dedication to quality is evident in the precision and durability of its products, making them a top choice for professionals around the world.In addition to manufacturing, also places a strong emphasis on research and development. The company continuously strives to improve its products and develop new, innovative solutions to meet the evolving needs of its customers.One of the key factors that sets apart from its competitors is its commitment to sustainability. The company has implemented eco-friendly practices in its manufacturing process, ensuring that its products are not only high-quality but also environmentally responsible.As a global leader in the industry, has established a strong presence in international markets. The company has a wide network of partners and distributors, allowing it to reach customers in various countries across the globe. is also known for its exceptional customer service. The company's team is dedicated to providing support and assistance to its customers, ensuring that they have a positive experience with its products.Recently, has introduced a new line of cast iron measuring tools designed to meet the growing demand for high-quality, reliable measurement instruments. These new products have been well-received by professionals in the industry, further solidifying 's position as a leader in the market.With a focus on quality, innovation, and sustainability, continues to set the standard for cast iron measuring tools. The company's dedication to excellence and commitment to its customers make it a top choice for professionals around the world.In conclusion, is a leading manufacturer of cast iron measuring tools, known for its commitment to quality, innovation, and sustainability. With a wide range of products, advanced manufacturing facilities, and exceptional customer service, continues to be a trusted name in the industry.

Ultimate Guide to Choosing the Best Welding Table for Your Needs" "Expert Tips for Selecting the Perfect Welding Table

Cast Iron Welding Table: The Perfect Solution for Heavy-Duty Welding ProjectsWelding is an essential part of the industrial world. From joining two pieces of metal to repairing heavy machinery, welding plays a crucial role in our lives. However, welding can be dangerous, and safety should be the top priority when performing any welding activity. That's why choosing the right welding equipment is as important as choosing the right technique.One of the most crucial pieces of equipment in welding is the welding table, and Cast Iron Welding Table stands out as one of the top choices in the market.The Cast Iron Welding Table is designed to provide maximum safety, durability, and versatility. The welding table is manufactured using high-quality cast iron material that ensures it can withstand even the toughest welding projects. Cast iron also offers excellent heat resistance, ensuring that the table doesn't warp or buckle under extreme heat, making it an ideal solution for heavy-duty welding projects.Moreover, Cast Iron Welding Tables come in a wide range of sizes, enabling welders to choose the perfect table that suits their needs. From small and portable welding tables to larger tables that can accommodate bigger welding projects, Cast Iron Welding Table has a solution for all welding needs.Additionally, the welding tables are designed with multiple features and accessories that provide maximum convenience, safety, and efficiency. Some of the features and accessories include:- Precision drilled holes: The welding tables are precision-drilled with evenly spaced holes that allow for easy clamping of workpieces. This feature ensures that workpieces are held firmly, providing maximum safety and accuracy during welding.- Slotted design: Some of the Cast Iron Welding Tables come with a slotted design that provides maximum flexibility when clamping workpieces at different angles.- Heat-resistant surface: Cast Iron Welding Tables come with a heat-resistant surface that withstands extreme heat and spatter from welding, ensuring that the table remains clean and safe for continued use.- Adjustable height: Welding tables come in adjustable heights, providing maximum comfort and reduced strain on the welder's back.These features and accessories make Cast Iron Welding Table a perfect solution for heavy-duty welding projects. Whether you're a professional welder or a DIY enthusiast, Cast Iron Welding Table is a reliable and high-quality option for welding activity.About the CompanyThe company behind Cast Iron Welding Table is a leading manufacturer of welding equipment. The company has been in the welding industry for over 20 years, and its focus has always been on designing and manufacturing high-quality and reliable welding equipment.The company prides itself on its commitment to safety, quality, and customer satisfaction. Each product is designed and manufactured with the best materials and advanced techniques, ensuring that their products meet the highest industry standards.The company has a wide range of products that cater to various welding needs, from welding tables to welding machines, welding accessories, and safety equipment. Their products are sold through various channels, including physical stores and online platforms.Moreover, the company offers excellent customer support and after-sales service, ensuring that customers get the best experience with their products. With their reputation for quality products and exceptional customer service, the company has built a loyal customer base that continues to grow.ConclusionWelding can be a dangerous activity, and safety should be a top priority when performing any welding projects. Choosing the right welding equipment is crucial for ensuring maximum safety, efficiency, and convenience. Cast Iron Welding Table is a reliable and high-quality option for heavy-duty welding projects. Designed with the best materials and advanced features, the welding tables provide maximum safety, durability, and versatility, making them a perfect solution for all welding needs.

Durable Welding Table for Steel Fabrication Projects

Steel Welding Table has emerged as a leading choice for welding professionals, hobbyists, and metalworking enthusiasts worldwide. The company has carved a niche for itself by manufacturing top-quality welding tables that are durable, versatile, and built to the highest standards. With a commitment to innovation and continuous improvement, Steel Welding Table has become the go-to brand for individuals and businesses seeking exceptional welding solutions.Founded in [year], Steel Welding Table has steadily grown its presence in the market and gained a reputation for delivering premium products that meet the diverse needs of its customers. The company's extensive range of welding tables caters to various welding applications, from industrial fabrication to automotive repair. By understanding the demands of the welding industry, Steel Welding Table has continually expanded its product lineup to offer a comprehensive selection of tables, accessories, and tools.The [company name] welding tables are engineered with precision and expertise, utilizing high-quality steel materials and advanced manufacturing techniques. Each table is meticulously crafted to provide a stable and reliable work surface for welding and metalworking tasks. The tables feature a flat and smooth platform, designed to withstand the rigors of welding operations while ensuring optimal accuracy and efficiency. Additionally, the tables are equipped with integrated features such as slots, clamps, and fixtures, enhancing their versatility and usability for a wide range of projects.One of the key highlights of Steel Welding Table's offerings is the attention to detail and practicality in its designs. The tables are designed to be adaptable and user-friendly, with ergonomic configurations that promote ease of use and productivity. Whether it's a small-scale DIY project or a large-scale production job, the tables from Steel Welding Table are engineered to deliver exceptional performance and support the needs of welders across different industries.In addition to its core range of welding tables, Steel Welding Table also offers a variety of complementary products and accessories to further enhance the functionality and convenience of its tables. From clamping systems to mounting brackets, the company provides a comprehensive selection of accessories that enable users to customize their welding setups according to their specific requirements. This versatility and modularity make Steel Welding Table a preferred choice for those seeking a complete welding solution that can adapt to evolving needs and applications.Furthermore, Steel Welding Table places a strong emphasis on customer satisfaction and support, aiming to provide an exceptional experience for its clientele. The company's dedication to quality, reliability, and service has earned it a loyal customer base and positive reviews within the welding community. With a commitment to continuous improvement and innovation, Steel Welding Table remains at the forefront of the industry, constantly refining its products and exploring new technologies to meet the evolving demands of the welding market.As Steel Welding Table continues to grow and expand its reach, the company remains dedicated to its core values of excellence, integrity, and customer-centricity. With a focus on delivering superior products and solutions, Steel Welding Table is poised to remain a trusted partner for welding professionals and enthusiasts alike.In conclusion, Steel Welding Table has established itself as a reputable and reliable provider of top-quality welding tables and accessories. With a strong commitment to innovation, customer satisfaction, and excellence, the company has cemented its position as a leader in the welding industry. As it continues to evolve and grow, Steel Welding Table is set to remain a go-to brand for individuals and businesses seeking superior welding solutions.

High-Quality Cast Iron Bed Plates for Manufacturing Applications

The renowned cast iron bed plates manufacturer has been making headlines lately with its innovative products and cutting-edge technology. With a rich history of over [XX] years in the industry, the company has established itself as a leader in the manufacturing of high-quality cast iron bed plates for various industrial applications.The company's journey began in [year] when it was founded by a team of passionate engineers and entrepreneurs. Since then, it has grown exponentially and has continuously expanded its product line to cater to the diverse needs of its customers. The company takes pride in its state-of-the-art manufacturing facilities, which are equipped with the latest machinery and technology to ensure precision and quality in every product.One of the key strengths of the company lies in its dedicated team of professionals who bring a wealth of experience and expertise to the table. From product design and development to manufacturing and quality control, the company's team works tirelessly to deliver top-notch cast iron bed plates that meet the highest standards of quality and performance.In addition to its commitment to quality, the company also places a strong emphasis on innovation. It continuously invests in research and development to stay ahead of the curve and bring new and improved products to the market. The company's constant drive for innovation has led to the development of advanced materials and designs that offer unparalleled performance and durability.Moreover, the company prides itself on its ability to customize its products to meet the specific requirements of its clients. Whether it's a unique design, size, or material specification, the company has the capability to tailor its products to suit the individual needs of its customers. This flexibility and customer-centric approach have earned the company a loyal and satisfied customer base across the globe.The company's cast iron bed plates find applications in a wide range of industries, including automotive, aerospace, energy, and heavy machinery. These bed plates are known for their superior flatness, dimensional stability, and resistance to wear and tear, making them the top choice for demanding applications where precision and reliability are paramount.In addition to its focus on product excellence, the company is also dedicated to sustainability and environmental responsibility. It has implemented various initiatives to reduce its environmental footprint, including the use of eco-friendly materials and energy-efficient manufacturing processes. By prioritizing sustainability, the company not only benefits the environment but also contributes to the long-term success and reputation of its brand.Looking ahead, the company has ambitious plans for the future. It aims to further expand its global presence and reach new markets, while continuing to push the boundaries of innovation and technology in the manufacturing of cast iron bed plates. With a strong foundation built on quality, innovation, and customer satisfaction, the company is well-positioned to achieve its goals and maintain its leadership position in the industry.In conclusion, the renowned cast iron bed plates manufacturer has established itself as a powerhouse in the industry, with its steadfast commitment to quality, innovation, and customer satisfaction. With a rich history, a talented team, and a focus on sustainability, the company is well-equipped to thrive in an ever-evolving market. As it continues to push the boundaries of manufacturing excellence, the company is set to shape the future of the industry and set new benchmarks for quality and innovation.

High-Quality Sand-Cast Pump Cover: Gray and Ductile Iron Materials Construction

Qingdao Donrex Co., Ltd., a leading cast iron and ductile iron parts manufacturer, recently announced the production of their new China sand-cast part pump cover. This pump cover is made from high-quality gray and ductile iron materials, ensuring durability and longevity.Sand casting is a process used for creating castings from molten metal poured into a sand mold. It is a versatile and cost-effective method, making it an ideal choice for the production of pump covers. Donrex Co., Ltd. has optimized the sand-casting process, using state-of-the-art technology to create high-quality pump covers.Pump covers are essential components in the construction and manufacturing industries. They are used to protect pumps from contaminants and provide access for maintenance and repairs. A high-quality pump cover ensures that the pump remains operational for an extended period, increasing productivity and efficiency.Donrex Co., Ltd.'s new China sand-cast part pump cover is made from gray and ductile iron materials, ensuring strength, durability, and corrosion resistance. Gray iron is widely used in the manufacturing industry for its excellent casting properties, machinability, and wear resistance. Ductile iron, also known as nodular iron, is a form of iron that has been treated with small amounts of magnesium to alter its physical properties, making it more ductile and flexible.The China sand-cast part pump cover from Donrex Co., Ltd. is designed to meet the highest industry standards. The pump covers undergo rigorous testing and inspection to ensure that they meet the required specifications. The company's commitment to quality is evident in the materials used, the manufacturing process, and the strict quality control measures.Donrex Co., Ltd. has a wealth of experience in designing and manufacturing cast iron and ductile iron parts. The company has a team of experts who are constantly innovating and improving their production processes to meet the changing demands of the industry. They pride themselves on meeting the needs of their clients, delivering quality products on time and within budget.The new China sand-cast part pump cover from Donrex Co., Ltd. is a testament to the company's commitment to innovation and quality. It is a product that meets the highest industry standards, ensuring that it will perform its intended function effectively and efficiently.In conclusion, the new China sand-cast part pump cover from Donrex Co., Ltd. is a high-quality product made from gray and ductile iron materials. It is a testament to the company's commitment to innovation and quality and is designed to meet the highest industry standards. As one of the leading cast iron and ductile iron parts manufacturers, Donrex Co., Ltd. continues to innovate and improve, delivering quality products that meet the changing demands of the industry.