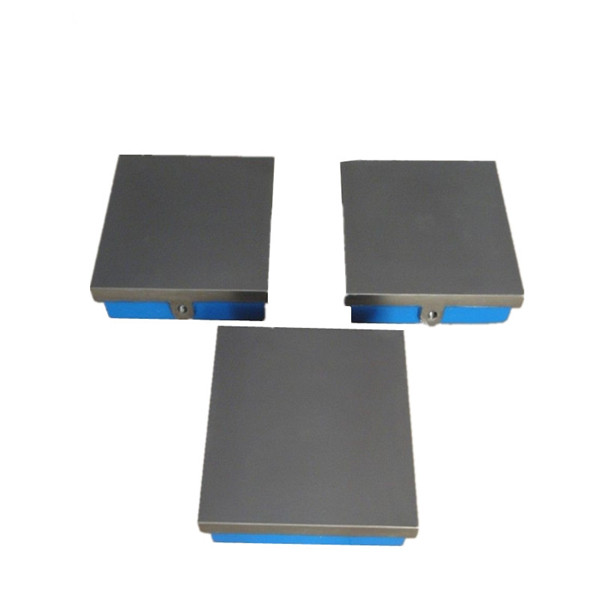

Durable and Precision Small Granite Surface Plate for Industrial Use

By:Admin

In today's fast-paced manufacturing industry, precision and accuracy are of utmost importance. From automotive to aerospace, numerous industries rely on high-quality measurement tools to ensure the quality of their products. This is where the Small Granite Surface Plate comes into play, offering superior precision and durability for various manufacturing applications.

Manufactured by a leading company in the industry, the Small Granite Surface Plate is designed to meet the demanding requirements of precision measurement and inspection. Made from high-quality black granite, the surface plate provides a stable and reliable base for measuring and inspecting various components. The dense, non-porous surface of the granite resists corrosion and wear, ensuring long-term accuracy and repeatability.

The Small Granite Surface Plate is available in a range of sizes and configurations to meet the specific needs of different manufacturing processes. Whether it is used for tool and die making, precision machining, or quality control, this surface plate provides a flat and level surface for accurate measurements. Its fine grain structure and low porosity make it an ideal choice for applications that require high precision and stability.

One of the key features of the Small Granite Surface Plate is its dimensional stability over time. Unlike other materials, such as steel or cast iron, granite has minimal thermal expansion, allowing for consistent measurements even in changing temperature environments. This makes the surface plate suitable for use in various manufacturing facilities, where temperature variations are common.

The Small Granite Surface Plate is also equipped with a precision ground surface, which is essential for achieving accurate measurements. The flatness and parallelism of the surface are carefully controlled during the manufacturing process to ensure the highest level of precision. Additionally, the surface plate is lapped to achieve a smooth and uniform finish, further enhancing its measurement capabilities.

In addition to its precision and durability, the Small Granite Surface Plate is also easy to maintain. It requires minimal upkeep and is resistant to common chemicals and solvents used in manufacturing processes. This makes it a cost-effective and reliable solution for long-term use in industrial settings.

The company behind the Small Granite Surface Plate has a long-standing reputation for delivering high-quality metrology products to the manufacturing industry. With a focus on innovation and customer satisfaction, the company has become a trusted provider of measurement solutions for a wide range of applications. Its team of skilled professionals ensures that every surface plate meets the highest standards of quality and performance.

The company takes pride in its state-of-the-art manufacturing facilities, where advanced technologies and processes are employed to produce precision measurement tools. Quality control measures are rigorously enforced throughout the production process to guarantee the accuracy and reliability of each surface plate. As a result, customers can rely on the Small Granite Surface Plate to deliver consistent and accurate measurements, enhancing their manufacturing operations.

Overall, the Small Granite Surface Plate offers a combination of high precision, durability, and ease of maintenance, making it an essential tool for the manufacturing industry. With its superior performance and reliability, it is a valuable asset for companies seeking to ensure the quality and integrity of their products. As the demand for precision measurement continues to grow, the Small Granite Surface Plate stands out as a trusted solution for achieving the highest standards of accuracy in manufacturing.

Company News & Blog

Testing the Durability and Quality of Cast Iron Plates: A Comprehensive Analysis

Title: High-Quality Testing Plate: Revolutionizing Quality Assurance in the Foundry IndustryIntroduction:In the highly competitive world of the foundry industry, the need for accurate and reliable quality assurance tools is paramount. To address this challenge, a leading company has developed a state-of-the-art Cast Iron Testing Plate. This innovative product revolutionizes the way foundries test the quality and integrity of their cast iron products. By utilizing cutting-edge technologies and meticulous design, the company has created a game-changing tool that ensures the production of superior cast iron components.I. Background on the Foundry Industry:The foundry industry plays a crucial role in the manufacturing sector, as it produces various cast iron parts and components used in a wide range of industries, including automotive, aerospace, construction, and more. The quality of these cast iron products is of utmost importance to ensure safe and reliable operation in their respective applications. Therefore, foundries must adopt rigorous quality control measures to uphold their reputation and meet the stringent industry standards.II. Introducing the Cast Iron Testing Plate:The newly launched Cast Iron Testing Plate by {Company} is designed to provide an accurate and efficient solution for quality assurance in the foundry industry. Made from high-grade cast iron, this testing plate is engineered to simulate the same properties found in cast iron parts, allowing foundries to perform extensive testing and analysis on their products.III. Unique Features and Benefits:a) Material Integrity: The Cast Iron Testing Plate is carefully crafted using premium cast iron, ensuring its durability and ability to withstand high temperatures. This feature enables efficient testing of various cast iron components while mimicking their characteristics accurately.b) Surface Finishing: The testing plate's surface is precisely machined to replicate common casting defects such as shrinkage, porosity, and surface roughness. This allows foundries to evaluate how their cast iron products would respond to these defects, enabling improvements in the production process.c) Dimensional Accuracy: The testing plate offers excellent dimensional accuracy with tight tolerances, enabling precise measurements and comparisons with cast iron components under analysis. Accurate measurement data aids in identifying any deviations and making necessary adjustments for enhanced product quality.d) Compatibility: The testing plate is designed to efficiently accommodate different testing methods, including non-destructive testing (NDT) techniques such as ultrasonic testing, magnetic particle inspection, x-ray inspection, and more. This versatility eliminates the need for multiple testing tools, reducing costs and improving efficiency.e) Cost-Effectiveness: By utilizing the Cast Iron Testing Plate, foundries can minimize costly production errors, reduce waste, and optimize their processes, leading to significant cost savings. Additionally, the longer lifespan of the testing plate ensures a long-term investment, allowing foundries to focus their resources on other critical aspects of their operations.IV. Industry Applications and Adoption:The innovative Cast Iron Testing Plate has gained swift recognition within the foundry industry due to its unmatched quality and reliability. Foundries worldwide have reported remarkable improvements in their production processes, resulting in higher customer satisfaction and greater market competitiveness. The ease of use, superior performance, and cost-effectiveness of the testing plate have made it a preferred choice for foundries seeking efficient quality assurance solutions.V. Conclusion:In conclusion, the Cast Iron Testing Plate developed by {Company} has revolutionized the quality assurance practices in the foundry industry. With its high-quality construction, accurate surface replication, and compatibility with various testing methods, this innovative tool enhances the overall productivity and reliability of cast iron components. As foundries strive to meet the ever-increasing demands of their customers, the Cast Iron Testing Plate serves as a reliable ally in their pursuit of exceptional quality, greater efficiency, and continuous improvement.

Quality Cast Iron Machine Bed for Sale - Buy Durable Machinery Parts

The company, with a rich history of producing high-quality machine parts, has recently announced the launch of their latest innovation - a cast iron machine bed. This new product is expected to revolutionize the industry with its high durability and precision engineering.The cast iron machine bed is manufactured using state-of-the-art technology and top-quality materials, ensuring that it meets the highest standards in the industry. It is designed to provide exceptional stability and support for various types of machinery, making it an ideal choice for manufacturers in a wide range of sectors.The company has a long-standing reputation for delivering superior products and has gained the trust of countless clients over the years. With their commitment to innovation and excellence, they have continuously pushed the boundaries of what is possible in the industry.The cast iron machine bed is the latest addition to their extensive product line, and it is set to become a game-changer for many businesses. Its robust construction and advanced design make it suitable for a variety of applications, from heavy-duty industrial machinery to precision engineering tools.One of the key features of the cast iron machine bed is its exceptional durability. Made from high-quality cast iron, it is built to withstand the toughest working conditions and provide reliable performance for years to come. This durability is essential for businesses looking to minimize downtime and maximize productivity.In addition to its strength, the machine bed is also meticulously engineered to ensure a high level of precision. Every detail, from its smooth surface to its exact measurements, has been carefully crafted to deliver optimal results. This precision is crucial for industries that require consistently accurate output.Moreover, the company's dedication to quality is evident in the rigorous testing and inspection processes that the cast iron machine bed undergoes before it is made available to customers. This ensures that every product meets the company's high standards and provides exceptional value to the end users.Customers can also expect outstanding support from the company, as they have a team of highly skilled professionals who are committed to providing expert guidance and assistance. Whether it is helping customers select the right product for their needs or offering technical support, the company is known for its exceptional customer service.The launch of the cast iron machine bed is a significant milestone for the company, and it is expected to have a far-reaching impact on the industry. With its unparalleled durability, precision engineering, and unwavering commitment to quality, it is set to become a sought-after product for manufacturers around the world.As businesses continue to demand more reliable and high-performance machinery, the cast iron machine bed offers a compelling solution that can help them stay ahead of the competition. Its ability to provide stability, support, and precision will undoubtedly make it an indispensable asset for many industries.In conclusion, the company's latest innovation, the cast iron machine bed, is a testament to their unwavering commitment to delivering cutting-edge products that meet the evolving needs of the industry. With its exceptional durability, precision engineering, and outstanding support, it is poised to set a new standard for machine beds and become a key player in the market. As businesses seek reliable and high-performance solutions, the cast iron machine bed is sure to make a lasting impact and solidify the company's position as a leader in the industry.

Advanced 3D Welding Tables for Modular Projects

Introducing a Revolutionary New Solution for Welding: 3D Modular Welding TablesWelding is a critical process in the manufacturing industry, and having the right equipment is essential for achieving high-quality results. That's why [Company Name] is proud to introduce a groundbreaking new solution for welding: 3D Modular Welding Tables. These innovative tables are set to revolutionize the way welding is done, offering unparalleled versatility, precision, and efficiency.[Company Name] has been a leader in providing cutting-edge solutions for the welding industry for over a decade. With a focus on innovation and quality, the company has continuously strived to develop products that meet the evolving needs of welders and fabricators. The introduction of 3D Modular Welding Tables is a testament to [Company Name]'s commitment to pushing the boundaries of what's possible in welding technology.The 3D Modular Welding Tables are designed to provide a comprehensive and flexible solution for a wide range of welding applications. Utilizing advanced 3D modeling and precision engineering, these tables offer unmatched accuracy and repeatability, ensuring that every weld is performed with the utmost precision. The modular design allows for easy customization, enabling welders to configure the tables to suit their specific needs and project requirements.One of the key features of the 3D Modular Welding Tables is their adaptability to various welding methods, including MIG, TIG, and Stick welding. This versatility makes these tables suitable for a diverse range of projects, from small-scale fabrication to large-scale industrial processes. Additionally, the tables are equipped with advanced clamping and fixturing systems, providing secure and stable support for workpieces of any size and shape.Moreover, the 3D Modular Welding Tables are constructed using high-quality materials that are built to withstand the rigors of the welding environment. The robust construction ensures durability and longevity, making these tables a wise investment for any welding operation. Furthermore, the tables are designed to be user-friendly, with intuitive controls and ergonomic features that make them easy to operate and maintain.In addition to their practical benefits, the 3D Modular Welding Tables also offer significant advantages in terms of efficiency and productivity. By streamlining the welding process and providing a stable and adaptable work surface, these tables can help welders complete their projects faster and with greater precision. This not only saves time and labor costs but also improves the overall quality of the finished welds.[Company Name] is committed to providing comprehensive support for its customers, and the introduction of the 3D Modular Welding Tables is no exception. In addition to offering high-quality products, the company also provides training and technical assistance to ensure that welders can make the most of their investment. This includes comprehensive instruction on using the tables effectively and efficiently, as well as ongoing support for any maintenance or troubleshooting needs.The introduction of 3D Modular Welding Tables represents a significant milestone for [Company Name] and the welding industry as a whole. With their unmatched precision, versatility, and efficiency, these tables are set to redefine the standards for welding equipment. Whether for small-scale fabrication or large-scale industrial projects, these tables offer a comprehensive solution that cater to the diverse needs of welders and fabricators.In conclusion, the introduction of 3D Modular Welding Tables marks a new era in welding technology, and [Company Name] is proud to be at the forefront of this exciting development. With their advanced features, user-friendly design, and comprehensive support, these tables are poised to become an indispensable tool for welders around the world. Whether for improving the quality of welds or streamlining the welding process, the 3D Modular Welding Tables are a game-changer that is sure to benefit the entire welding industry.

High-Quality Steel Wedged Products for Multiple Applications

Steel Wedged Products, a leading manufacturer of cutting-edge industrial tools, is taking the industry by storm with its innovative and high-quality products. With a strong focus on technology and customer satisfaction, the company has established itself as a leader in the market and continues to set new standards in the industry.Steel Wedged Products is dedicated to providing top-of-the-line tools and equipment to its customers, catering to a wide range of industries including construction, automotive, mining, and agriculture. The company offers a diverse range of products including cutting tools, machining tools, and machine parts, all of which are designed to meet the highest standards of quality and performance.A key factor that sets Steel Wedged Products apart from its competitors is its relentless pursuit of innovation. The company invests heavily in research and development to constantly improve its products and stay ahead of the curve. This commitment to innovation has allowed Steel Wedged Products to introduce cutting-edge technologies and solutions that have revolutionized the industry.One such example of Steel Wedged Products’ innovation is its advanced cutting tools, which are designed to deliver unmatched precision and efficiency. These tools are engineered with state-of-the-art materials and manufacturing techniques, ensuring superior performance and extended durability. Customers can rely on Steel Wedged Products’ cutting tools to deliver outstanding results, even in the most demanding applications.In addition to its innovative products, Steel Wedged Products is also renowned for its exceptional customer service. The company takes great pride in its ability to understand the unique needs of its customers and provide tailored solutions that exceed their expectations. Whether it’s providing expert technical advice or delivering custom-made tools, Steel Wedged Products goes above and beyond to ensure customer satisfaction.Furthermore, Steel Wedged Products is committed to upholding the highest standards of quality and safety. The company’s products undergo rigorous testing and inspection processes to guarantee their reliability and performance. With certifications and accreditations from industry authorities, customers can have full confidence in the quality and safety of Steel Wedged Products’ products.As a testament to its success and leadership in the industry, Steel Wedged Products has established a strong presence in both domestic and international markets. The company’s products are widely distributed and used by leading businesses and organizations around the world, further solidifying its reputation as a trusted and preferred supplier.Looking ahead, Steel Wedged Products is poised for continued growth and success. The company remains dedicated to pushing the boundaries of innovation and delivering unparalleled value to its customers. With a team of skilled professionals and a clear vision for the future, Steel Wedged Products is well positioned to maintain its position as a frontrunner in the industry.In conclusion, Steel Wedged Products stands out as a powerhouse in the industrial tools and equipment sector. With its unwavering commitment to innovation, quality, and customer satisfaction, the company continues to raise the bar and set new benchmarks for excellence. As it forges ahead, Steel Wedged Products will undoubtedly remain a force to be reckoned with in the industry.

Discover the Latest Trends in Triangular Rulers Manufacture

Granite Triangular Ruler Manufacturer Excels in Precision EngineeringIn the world of precision engineering and measurement, Granite Triangular Ruler Factory has built an impeccable reputation for its exceptional craftsmanship and quality products. With a focus on precision and accuracy, this innovative manufacturer has become a leading player in the industry.Established in 1985, the company has a rich history of delivering high-quality triangular rulers to various sectors, including engineering, construction, and manufacturing. Granite Triangular Ruler Factory prides itself on its commitment to excellence and constant pursuit of perfection.What sets Granite Triangular Ruler Factory apart from its competitors is its unwavering dedication to precision engineering. The company employs state-of-the-art technology and equipment to ensure that each triangular ruler produced meets the highest standards of accuracy. From the initial design phase to the final product, every step of the manufacturing process is meticulously monitored and controlled.One of the key factors that contribute to Granite Triangular Ruler Factory's success is its use of granite as the primary material for its triangular rulers. Granite is highly regarded for its exceptional stability, durability, and resistance to wear and tear. By utilizing this premium material, the company ensures that its triangular rulers maintain their accuracy and integrity over a prolonged period.Granite Triangular Ruler Factory's commitment to providing customers with reliable and accurate measuring tools extends beyond its products. The company also places great emphasis on customer satisfaction and strives to build long-lasting relationships with its clients. Whether it's addressing inquiries, providing technical support, or offering customized solutions, Granite Triangular Ruler Factory aims to exceed customer expectations in every aspect of its operations.The company's dedication to innovation is evident in its continuous research and development efforts. Granite Triangular Ruler Factory recognizes the importance of keeping up with technological advancements and evolving market demands. By investing in research and development, the company ensures that its products remain at the forefront of precision engineering, meeting the ever-growing needs of its customers.Granite Triangular Ruler Factory's commitment to environmental sustainability is also noteworthy. As a responsible manufacturer, the company strives to minimize its carbon footprint by implementing eco-friendly production processes. From using renewable energy sources to reducing waste and recycling materials, Granite Triangular Ruler Factory demonstrates its commitment to preserving the environment for future generations.With a strong presence in both domestic and international markets, Granite Triangular Ruler Factory has emerged as a trusted brand among professionals in various industries. Its products are highly regarded for their accuracy, durability, and exceptional craftsmanship. By consistently delivering on its promises, the company has garnered a loyal customer base that values quality and precision.As the demand for precision measurement tools continues to grow, Granite Triangular Ruler Factory remains committed to providing innovative solutions that meet and exceed industry standards. With its unwavering dedication to precision engineering, customer satisfaction, and environmental sustainability, the company is poised to remain at the forefront of the industry for years to come.

Versatile Welding Table System for Efficient Workholding

Modular Welding Table System Revolutionizes Welding IndustryWelding has always been an essential part of various industries, from construction to manufacturing. Welders often face challenges in achieving precision and efficiency in their work. However, the introduction of the innovative Modular Welding Table System has revolutionized the welding industry, offering a game-changing solution to these challenges.This cutting-edge welding system is the brainchild of a leading manufacturing company (Company Name), widely recognized for its commitment to engineering excellence and product innovation. With a strong emphasis on quality and performance, (Company Name) has continuously strived to develop advanced solutions that cater to the evolving needs of the welding industry.The Modular Welding Table System is a testament to (Company Name’s) dedication to providing welders with state-of-the-art tools that enhance productivity and accuracy. This innovative system consists of a versatile range of modular welding tables, clamping systems, and accessories, all designed to provide a flexible and efficient work surface for welding applications.One of the key features of the Modular Welding Table System is its modular design, which allows welders to easily assemble and reconfigure the tables to accommodate various welding projects. This flexibility is a game-changer for welders, as it eliminates the need for multiple fixed welding tables, saving time, space, and resources.Furthermore, the welding tables are equipped with a grid of bore holes, enabling welders to position and secure workpieces with precision using a range of clamping devices. This level of customization and adaptability ensures that welders can achieve the highest level of accuracy in their work, ultimately resulting in top-quality welds.The Modular Welding Table System also boasts compatibility with a range of accessories, including stop bars, angle brackets, and magnetic holders, further enhancing its functionality and versatility. These accessories provide welders with the necessary tools to streamline their workflow and tackle a wide array of welding tasks with ease.In addition to its innovative design, the Modular Welding Table System prioritizes durability and stability, ensuring that it can withstand the rigors of industrial welding operations. The tables are constructed from high-quality materials, offering a robust and reliable work surface that can withstand the intense heat and pressure associated with welding.The introduction of the Modular Welding Table System has been met with widespread acclaim within the welding industry, as it addresses many of the challenges that welders face on a daily basis. Welders have praised the system for its ability to streamline their workflow, improve precision, and ultimately enhance the quality of their welds.Furthermore, (Company Name) has provided comprehensive training and support for welders looking to integrate the Modular Welding Table System into their operations. This commitment to customer satisfaction exemplifies (Company Name’s) dedication to providing holistic solutions that empower welders to achieve their best work.As the demand for high-quality welding solutions continues to grow, (Company Name) remains at the forefront of innovation, continuously developing new technologies and solutions that push the boundaries of what is possible in the welding industry. The Modular Welding Table System is a shining example of (Company Name's) commitment to engineering excellence and its determination to drive positive change in the welding industry.In conclusion, the Modular Welding Table System has reshaped the landscape of the welding industry, setting a new standard for precision, efficiency, and versatility. With its innovative design, durability, and compatibility with a range of accessories, this system has empowered welders to elevate their craft and deliver top-quality welds with ease. As (Company Name) continues to lead the way in engineering advancements, the welding industry can look forward to a future filled with groundbreaking solutions that push the boundaries of what is possible.

High-Quality Suppliers of Cast Iron Surface Plates for Industrial Use

Cast Iron Surface Plate Suppliers Celebrate Decades of Excellence in Providing High-Quality Industrial Equipment[Supplier's name], a leading provider of cast iron surface plates, is celebrating decades of success and excellence in the manufacturing and supply of industrial equipment. Since their establishment in [year], they have been a trusted supplier to countless industries, offering a wide range of high-quality products and exceptional customer service.Their cast iron surface plates are renowned for their durability, precision, and reliability, making them an essential tool for industries such as automotive, aerospace, construction, and manufacturing. These surface plates are used for various applications, including precision assembly, layout, and inspection of machinery and equipment. [Supplier's name] takes pride in delivering products that meet the highest standards of quality and performance, ensuring the satisfaction and success of their customers.The company's commitment to excellence is evident in their state-of-the-art manufacturing facilities, where skilled craftsmen and advanced machinery work together to produce superior cast iron surface plates. They use high-quality materials and adhere to strict quality control measures throughout the production process, resulting in products that are built to last and perform under the most demanding conditions.In addition to their standard product line, [Supplier's name] also offers custom solutions to meet the unique needs of their clients. Their team of experienced engineers and technicians collaborate closely with customers to design and produce specialized surface plates tailored to specific applications and requirements. This personalized approach sets them apart from other suppliers and allows them to serve a diverse range of industries with precision and efficiency.As a customer-centric company, [Supplier's name] places great emphasis on providing exceptional service and support to their clients. Their knowledgeable and friendly staff are dedicated to assisting customers with product selection, technical inquiries, and after-sales support. They strive to build strong, long-lasting relationships with their clients, earning their trust and loyalty through their unwavering commitment to satisfaction.The company also prides itself on its environmental responsibility and sustainability efforts. [Supplier's name] is dedicated to minimizing their ecological footprint by implementing eco-friendly practices in their manufacturing processes and utilizing recyclable materials whenever possible. They are committed to contributing to a greener and more sustainable future for the industry and the planet.Over the years, [Supplier's name] has built a solid reputation as a dependable and innovative supplier of industrial equipment, earning the trust and respect of customers and partners worldwide. Their relentless pursuit of excellence and continuous improvement has propelled them to the forefront of the industry, establishing them as a top choice for businesses seeking high-quality cast iron surface plates and related products.As they celebrate their decades of success, [Supplier's name] remains steadfast in their commitment to providing superior products, exceptional service, and unwavering reliability to their valued customers. They look forward to continuing their legacy of excellence and innovation, further solidifying their position as a leader in the industry.To learn more about [Supplier's name] and their comprehensive range of cast iron surface plates and industrial equipment, please visit their website or contact their sales team for further information. With their dedication to quality, customer satisfaction, and environmental stewardship, [Supplier's name] is poised to shape the future of industrial equipment for many years to come.

Discover the Innovative 3D Worktable Made from Cast Iron

[Title]: Revolutionary Cast Iron 3D Worktable Unveiled by Innovation-Focused Company[Subtitle]: Company X Introduces Cutting-Edge Worktable to Boost Productivity in the Manufacturing Industry[Date][CITY], [State] - Company X, a renowned pioneer in the field of industrial innovation, has recently unveiled its latest breakthrough: a revolutionary Cast Iron 3D Worktable. This remarkable creation is set to redefine manufacturing processes, elevate productivity, and augment the precision of industrial operations.The Cast Iron 3D Worktable has been meticulously designed to offer manufacturers an unparalleled level of efficiency and accuracy in their operations. Through a combination of state-of-the-art technology and robust construction, this innovative worktable promises to revolutionize the manufacturing industry.This cutting-edge worktable is constructed using high-quality cast iron, celebrated for its durability and stability. The solid iron structure ensures a rigid foundation, allowing for seamless and precise machining operations. The utilization of cast iron guarantees optimal stability and minimizes vibrations, resulting in superior precision during manufacturing processes.While cast iron worktables are not a new concept, Company X brings a unique touch to the table, leveraging its extensive experience in the field. By integrating advanced 3D technology, Company X has succeeded in enhancing the traditional cast iron worktable, making it more versatile and suitable for modern manufacturing demands.The Cast Iron 3D Worktable utilizes a sophisticated numerical control system, enabling it to seamlessly integrate with computer-aided design (CAD) and computer-aided manufacturing (CAM) software. This cutting-edge technology facilitates the creation of intricate and complex parts with utmost precision, significantly reducing the margin for error. The worktable's compatibility with CAD/CAM systems grants manufacturers the ability to seamlessly translate virtual designs into tangible products.Additionally, the 3D capabilities of the worktable allow for the creation of prototypes, providing manufacturers with the opportunity to evaluate and refine their designs before initiating full-scale production. This powerful tool aids in identifying potential flaws or necessary improvements, ensuring the end product meets the highest standards of quality and functionality.Company X's commitment to innovation extends beyond the development of the Cast Iron 3D Worktable. With a strong focus on research and development, the company constantly pushes the boundaries of what is achievable within the manufacturing industry. By investing in cutting-edge technologies and recruiting top-tier talent, Company X ensures it remains at the forefront of industrial innovation.Furthermore, Company X recognizes the importance of sustainable practices and environmental responsibility. Not only does the Cast Iron 3D Worktable contribute to increased productivity and efficiency, but its durable construction also ensures its longevity, minimizing waste and reducing the need for frequent replacements. By prioritizing sustainability, Company X sets a prime example in the industry and encourages other manufacturers to follow suit.The introduction of the Cast Iron 3D Worktable marks a significant milestone for Company X and the manufacturing industry as a whole. Through this groundbreaking innovation, manufacturers can expect enhanced accuracy, improved efficiency, and increased productivity. This pioneering worktable empowers companies to unleash their creativity, accelerating the pace of production and ultimately contributing to the advancement of various sectors reliant on manufacturing processes.In conclusion, Company X's Cast Iron 3D Worktable represents a massive leap forward in the realm of industrial innovation. By combining the robustness of cast iron with advanced 3D technology, the worktable delivers unprecedented precision and versatility to manufacturers. The integration of CAD/CAM compatibility and prototyping capabilities ensures manufacturers can achieve exceptional quality and efficiency in their operations. Company X's unwavering commitment to sustainable practices and continuous research and development solidify its position as an industry leader. As the manufacturing industry evolves, Company X stands ready to shape its future with groundbreaking creations like the Cast Iron 3D Worktable.

High-Quality 3D Worktable Made of Cast Iron: A Durable Option for Your Projects

[Company Name], a leading manufacturer in the field of industrial equipment, has recently introduced the new Cast Iron 3D Worktable to its product line. The company, known for its high-quality and innovative solutions in the industrial sector, is set to revolutionize the market with this latest addition to its range of products.The Cast Iron 3D Worktable is designed to provide unparalleled precision and stability for various machining and manufacturing processes. Made from high-quality cast iron, the worktable offers exceptional durability and strength, making it suitable for heavy-duty applications. The 3D design allows for multi-axis machining with ease, enabling users to achieve complex and precise results with efficiency.One of the key features of the Cast Iron 3D Worktable is its modular design, which allows for flexibility and customization according to the specific requirements of the user. With a range of accessories and add-ons available, the worktable can be tailored to suit different applications, making it a versatile and valuable addition to any industrial setup.In addition to its exceptional build quality and versatility, the Cast Iron 3D Worktable also incorporates advanced technology for enhanced performance. The worktable is compatible with various CNC systems, allowing for seamless integration into existing machining processes. This ensures optimal efficiency and productivity, ultimately leading to cost savings and improved output for businesses.Furthermore, [Company Name] has emphasized the importance of safety in the design of the Cast Iron 3D Worktable. The worktable features built-in safety measures to protect users and equipment during operation, providing peace of mind and creating a secure working environment.The introduction of the Cast Iron 3D Worktable reflects [Company Name]'s commitment to constantly innovating and delivering cutting-edge solutions to meet the evolving needs of the industrial sector. With a strong focus on quality, performance, and reliability, the company has established itself as a trusted partner for businesses looking to optimize their manufacturing processes.Commenting on the launch of the Cast Iron 3D Worktable, [Company Name] spoke about the company's vision for the product and its potential impact on the market. The spokesperson stated, "We are thrilled to bring the Cast Iron 3D Worktable to the market. This product represents our dedication to providing advanced solutions that empower our customers to achieve excellence in their operations. We believe that the worktable will set new standards in precision and efficiency, and we are excited to see the positive outcomes it will deliver for our clients."The Cast Iron 3D Worktable is now available for purchase, and [Company Name] has expressed confidence in the product's success. With its solid build, advanced technology, and user-friendly design, the worktable is expected to be well-received by businesses seeking reliable and high-performance equipment for their industrial needs.For more information about the Cast Iron 3D Worktable and other products offered by [Company Name], interested parties are encouraged to visit the company's website or contact their sales representatives for personalized assistance.

High-Quality Machine Parts for Granite Cutting and Fabrication

Granite Machine Parts Introduces Cutting-Edge Manufacturing TechnologyGranite Machine Parts has been a trusted name in the manufacturing industry for over two decades. From its humble beginnings as a small workshop, the company has grown to become a leading provider of precision machine parts for a wide range of industries. With a commitment to quality, innovation, and customer satisfaction, Granite Machine Parts has continually sought to improve its manufacturing processes and capabilities.Recently, Granite Machine Parts made a significant investment in new cutting-edge manufacturing technology, further solidifying its position as a leader in the industry. The company's latest acquisition includes state-of-the-art machining equipment and advanced software that will allow for increased precision and efficiency in the production of machine parts.The new technology will enable Granite Machine Parts to take on more complex and intricate projects, while also improving the overall quality and accuracy of its products. This investment is a testament to the company's dedication to staying at the forefront of technological advancements in the manufacturing sector."We are thrilled to introduce this new technology into our manufacturing process," said [company spokesperson]. "This investment represents our ongoing commitment to providing the highest quality machine parts to our customers. With this new equipment, we will be able to take on more challenging projects and deliver even greater precision and accuracy in our products."The new machinery is equipped with advanced features such as multi-axis capabilities, high-speed cutting, and automated tool changing, allowing for faster and more precise manufacturing. Additionally, the accompanying software provides advanced modeling and simulation tools, which will streamline the design and production process, ultimately reducing lead times for customers.Granite Machine Parts has always been known for its meticulous attention to detail and commitment to exceeding customer expectations. With the addition of this cutting-edge technology, the company is poised to further elevate its capabilities and deliver even greater value to its clients.In addition to improving its manufacturing capabilities, Granite Machine Parts has also focused on enhancing its quality control processes. With the new technology, the company can more accurately inspect and verify the dimensions and specifications of each part, ensuring that they meet the highest standards of quality and precision."We believe that this investment will not only benefit our own operations, but also our customers, as they will receive even better products with improved lead times," [company spokesperson] added. "We are excited to see the positive impact this technology will have on our business and on the industries we serve."Granite Machine Parts has always prided itself on its ability to adapt to the ever-changing demands of the manufacturing industry. The company's commitment to innovation, quality, and customer satisfaction has been the driving force behind its success, and this recent investment in cutting-edge technology is a testament to that commitment.As Granite Machine Parts continues to grow and evolve, it remains dedicated to providing the highest quality machine parts and exceptional service to its customers. With its latest technological advancements, the company is well-positioned to continue leading the way in precision machining and manufacturing for years to come.