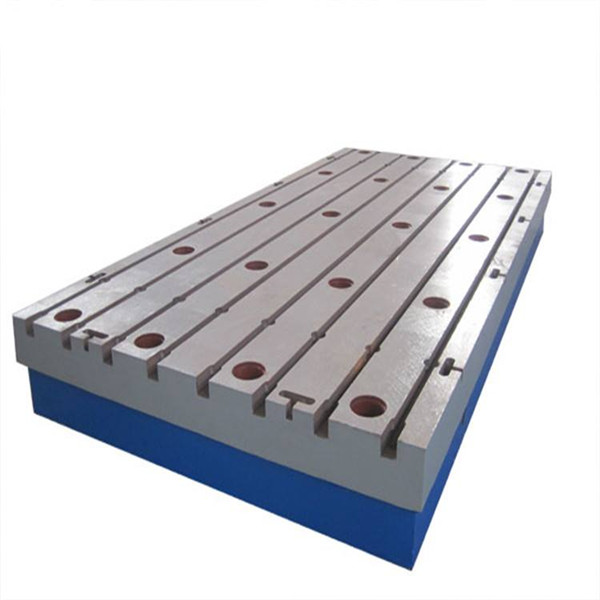

| 4000x2000x200mm | 3000x2000x200mm |

| 3000x1500x200mm | 2000x1500x200mm |

| 2400x1200x200mm | 2000x1000x200mm |

| 1500x1000x200mm | 1200x1000x200mm |

| 1000x1000x200mm | 5000x2000x200mm |

| 4000x2500x200mm | 3000x2500x200mm |

| 4000x1500x200mm | 4000x1000x200mm |

| 2500x1500x200mm | 3000x1000x200mm |

| 2500x1000x200mm | 2000x2000x200mm |

| 1500x1500x200mm | 1200x1200x200mm |

| 2000x1500x150mm | 2000x1000x150mm |

| 2400x1200x150mm | 1500x1000x150mm |

| 1200x1000x150mm | 1000x1000x150mm |

| 2000x1500mm | 2000x1000mm |

| 2400x1200mm | 1500x1000mm |

| 1200x1000mm | 1000x1000mm |

| 1200x800mm | 1200x1200mm |

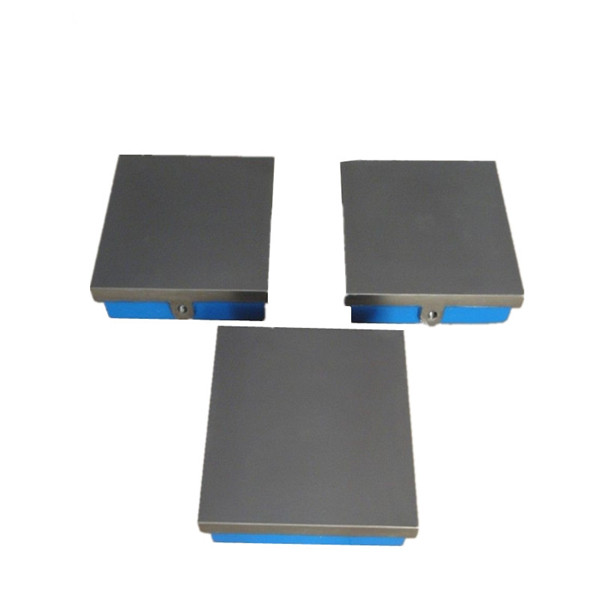

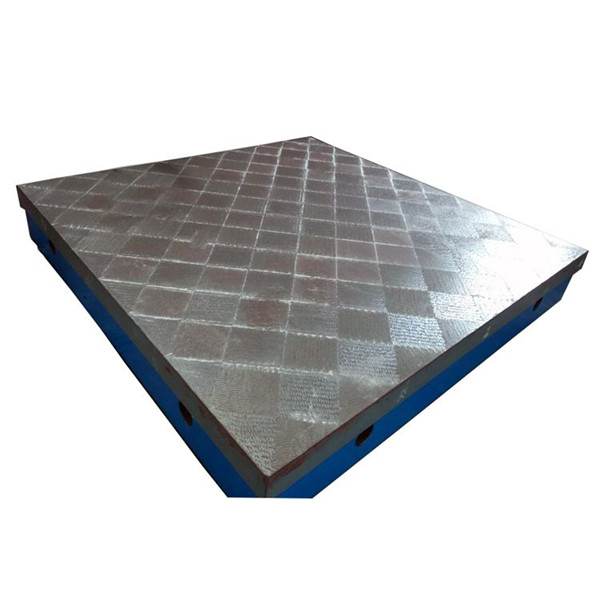

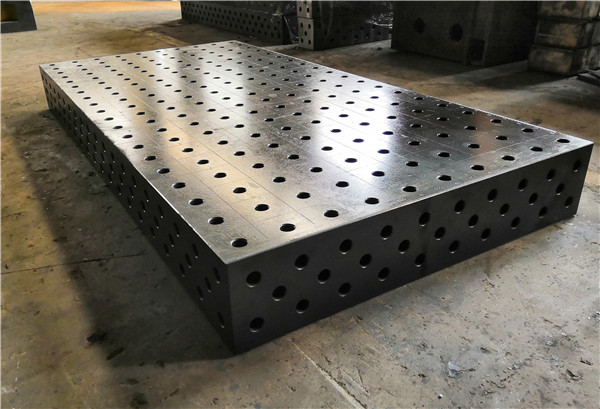

We can customize welding tables of different sizes according to your requirements 3D Welding table: five working surfaces the locating piece can be installed on. Also can be extended via any of its five working surfaces. • For its material divided into: Steel Welding Tables and Cast iron Welding Tables • For its hole diameter divided into: D28 series ,D22 series and D16 series. Diagonal Grid: D28 and D22 is 100*100mm; D16 is 50*50mm Supporting: legs, steel frame according to the requirement. 3D Welding Tables And Fixtures components can be equipped after your selecting: 1, Tools for supporting: U-Shaped cube case, L-shaped cube case, Angle supporting, and Angle gauge 2, spare parts for Locating: 3, Tools for clamping and fixing 4, spare parts for locking working piece 5, Auxiliary Tools Modular Welding Tables Features • Almost all workpiece can be fixed precisely at certain points or surfaces with locating piece, adapting piece, fastening piece and supporting piece, in the process of assembling or welding. • Imprecise dimensions of workpiece can be adjusted during preliminary working process. • It is easy to use existing parts in the workshop to imitate workpiece assembly via CAD. Economical working welding fabrication table • Save much cost instead of reserving a lot of complicated and expensive traditional fixtures • Applies to various working conditions without the need of any modification • Easy and safe to operate. Flexible 3d Welding Table • Solid enough to bear extremely heavy loads. • Five surfaces, regular holes and grid lines(no inclined holes or T-shaped grooves) • Any workpiece can be fixed and clamped on the table with locating pins • 3D welding tables can link together against any of its five surfaces. Precise welding tables • Almost all workpiece can be fixed precisely at certain points or surfaces with locating piece, adapting piece, fastening piece and supporting piece, in the process of assembling or welding • Imprecise dimensions of workpiece can be adjusted during preliminary working process.

We can customize welding tables of different sizes according to your requirements 3D Welding table: five working surfaces the locating piece can be installed on. Also can be extended via any of its five working surfaces. • For its material divided into: Steel Welding Tables and Cast iron Welding Tables • For its hole diameter divided into: D28 series ,D22 series and D16 series. Diagonal Grid: D28 and D22 is 100*100mm; D16 is 50*50mm Supporting: legs, steel frame according to the requirement. 3D Welding Tables And Fixtures components can be equipped after your selecting: 1, Tools for supporting: U-Shaped cube case, L-shaped cube case, Angle supporting, and Angle gauge 2, spare parts for Locating: 3, Tools for clamping and fixing 4, spare parts for locking working piece 5, Auxiliary Tools Modular Welding Tables Features • Almost all workpiece can be fixed precisely at certain points or surfaces with locating piece, adapting piece, fastening piece and supporting piece, in the process of assembling or welding. • Imprecise dimensions of workpiece can be adjusted during preliminary working process. • It is easy to use existing parts in the workshop to imitate workpiece assembly via CAD. Economical working welding fabrication table • Save much cost instead of reserving a lot of complicated and expensive traditional fixtures • Applies to various working conditions without the need of any modification • Easy and safe to operate. Flexible 3d Welding Table • Solid enough to bear extremely heavy loads. • Five surfaces, regular holes and grid lines(no inclined holes or T-shaped grooves) • Any workpiece can be fixed and clamped on the table with locating pins • 3D welding tables can link together against any of its five surfaces. Precise welding tables • Almost all workpiece can be fixed precisely at certain points or surfaces with locating piece, adapting piece, fastening piece and supporting piece, in the process of assembling or welding • Imprecise dimensions of workpiece can be adjusted during preliminary working process.