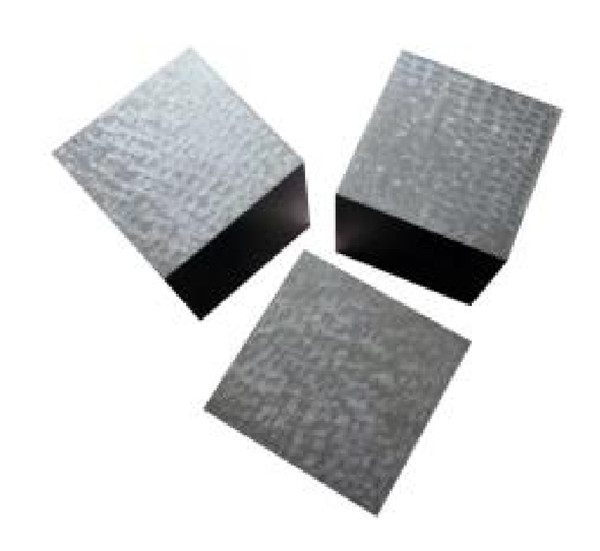

Technical requirements for Steel wedge: the accuracy is determined according to needs, because wedge generally uses upper and lower sides, so the requirements for the four sides are generally not high, and the roughness of the steel wedge is 6.4 ; The roughness of the upper and lower surfaces of the wedge is 12.5, 6.4, 3.2, 0.8, etc., if the accuracy is higher, the flatness and parallelism of the steel wedge processed by the grinder may not exceed 0.03mm. The thickness of the steel wedge can be determined according to actual needs and the material and specifications of the material; the slope of the steel wedge should be 1/10-1/20, the steel wedge of vibration or precision equipment The slope of the shim) can be 1/40. When using steel wedge, it should be used in conjunction with the flat shim of the same specification. The steel wedge should be used in pairs. The same slope should be used. The drawings of the steel wedge are designed according to the actual equipment base requirements, and then processed according to the drawings. How to use the steel wedge Place a flat shim on the concrete foundation, and then place the two steel wedge on the flat shim. When adjusting, use a hammer to hit two steel wedges, the slope of the steel wedge is used to raise or lower the equipment to achieve the purpose of adjusting the level. After the level is adjusted, spot weld the steel wedge with the base of the equipment to make the shim firm and firm. Finally, it is poured with concrete to keep the equipment in a good level during operation, reduce machine wear and tear, and reduce the cost of replacing equipment parts.

Technical requirements for Steel wedge: the accuracy is determined according to needs, because wedge generally uses upper and lower sides, so the requirements for the four sides are generally not high, and the roughness of the steel wedge is 6.4 ; The roughness of the upper and lower surfaces of the wedge is 12.5, 6.4, 3.2, 0.8, etc., if the accuracy is higher, the flatness and parallelism of the steel wedge processed by the grinder may not exceed 0.03mm. The thickness of the steel wedge can be determined according to actual needs and the material and specifications of the material; the slope of the steel wedge should be 1/10-1/20, the steel wedge of vibration or precision equipment The slope of the shim) can be 1/40. When using steel wedge, it should be used in conjunction with the flat shim of the same specification. The steel wedge should be used in pairs. The same slope should be used. The drawings of the steel wedge are designed according to the actual equipment base requirements, and then processed according to the drawings. How to use the steel wedge Place a flat shim on the concrete foundation, and then place the two steel wedge on the flat shim. When adjusting, use a hammer to hit two steel wedges, the slope of the steel wedge is used to raise or lower the equipment to achieve the purpose of adjusting the level. After the level is adjusted, spot weld the steel wedge with the base of the equipment to make the shim firm and firm. Finally, it is poured with concrete to keep the equipment in a good level during operation, reduce machine wear and tear, and reduce the cost of replacing equipment parts.Steel wedge

Get high-quality steel wedges for your construction needs straight from our factory. Our durable products ensure maximum stability and safety. Order today!

Request a QuotePRODUCTS DETAILS

Technical requirements for Steel wedge: the accuracy is determined according to needs, because wedge generally uses upper and lower sides, so the requirements for the four sides are generally not high, and the roughness of the steel wedge is 6.4 ; The roughness of the upper and lower surfaces of the wedge is 12.5, 6.4, 3.2, 0.8, etc., if the accuracy is higher, the flatness and parallelism of the steel wedge processed by the grinder may not exceed 0.03mm. The thickness of the steel wedge can be determined according to actual needs and the material and specifications of the material; the slope of the steel wedge should be 1/10-1/20, the steel wedge of vibration or precision equipment The slope of the shim) can be 1/40. When using steel wedge, it should be used in conjunction with the flat shim of the same specification. The steel wedge should be used in pairs. The same slope should be used. The drawings of the steel wedge are designed according to the actual equipment base requirements, and then processed according to the drawings. How to use the steel wedge Place a flat shim on the concrete foundation, and then place the two steel wedge on the flat shim. When adjusting, use a hammer to hit two steel wedges, the slope of the steel wedge is used to raise or lower the equipment to achieve the purpose of adjusting the level. After the level is adjusted, spot weld the steel wedge with the base of the equipment to make the shim firm and firm. Finally, it is poured with concrete to keep the equipment in a good level during operation, reduce machine wear and tear, and reduce the cost of replacing equipment parts.

Technical requirements for Steel wedge: the accuracy is determined according to needs, because wedge generally uses upper and lower sides, so the requirements for the four sides are generally not high, and the roughness of the steel wedge is 6.4 ; The roughness of the upper and lower surfaces of the wedge is 12.5, 6.4, 3.2, 0.8, etc., if the accuracy is higher, the flatness and parallelism of the steel wedge processed by the grinder may not exceed 0.03mm. The thickness of the steel wedge can be determined according to actual needs and the material and specifications of the material; the slope of the steel wedge should be 1/10-1/20, the steel wedge of vibration or precision equipment The slope of the shim) can be 1/40. When using steel wedge, it should be used in conjunction with the flat shim of the same specification. The steel wedge should be used in pairs. The same slope should be used. The drawings of the steel wedge are designed according to the actual equipment base requirements, and then processed according to the drawings. How to use the steel wedge Place a flat shim on the concrete foundation, and then place the two steel wedge on the flat shim. When adjusting, use a hammer to hit two steel wedges, the slope of the steel wedge is used to raise or lower the equipment to achieve the purpose of adjusting the level. After the level is adjusted, spot weld the steel wedge with the base of the equipment to make the shim firm and firm. Finally, it is poured with concrete to keep the equipment in a good level during operation, reduce machine wear and tear, and reduce the cost of replacing equipment parts.Contact us

Please feel free to give your inquiry in the form below We will reply you in 24 hours